Looking to the Future About

Joint-Development of the Structural Protein “Brewed Protein™” with Spiber Inc.

Vision

Aiming to Realize a Sustainable Society

Presently, most sports apparel items available on the market are produced using synthetic polymers such as polyester or nylon.

Many of these materials are made from petroleum, a resource created over hundreds of millions of years as organic matter such as plankton and algae is exposed to high pressure and heat underground. In the last few hundred years, humans have removed vast quantities of petroleum from the ground for consumption, causing various pressing environmental issues, including sudden changes in weather and temperature patterns due to the increasing concentration of carbon dioxide in Earth’s atmosphere, and increasing levels of air and sea pollution.

Market costs for many products which use petroleum-derived materials do not take into account the environmental and social costs of their use. The world is presently full of petroleum products that are cheap and easy to produce.

We therefore believe it is the duty of this generation to shift away from a short-term, consumerist economic model based on the use of petroleum resources, and to move towards a sustainable, long-term economic model based on the use of renewable and recyclable resources.

Through a joint research and development initiative between Goldwin and Spiber, we are striving to re-evaluate the relationship between nature and mankind. By balancing functionality with environmental considerations, and examining the role of products and the economy, we hope to create sports apparel that can support a lifestyle in harmony with nature. We believe we can thereby contribute significantly to the development of a sustainable world. This belief drives our continued effort towards this goal.

Development History

R&D to Reproduce Spider Silk Leads to Brewed Protein™, Offering Diverse Design Possibilities

Goldwin and Spiber’s collaboration began in 2015, sparked by a shared passion for addressing global-scale environmental problems. The joint research and development initiative began with a focus on replicating spider silk, a natural structural protein material, to use in apparel products. One of the biggest challenges in utilizing fibroin—the protein found in natural spider silk—for an application such as the outer shell layer of the MOON PARKA®, launched in October 2015, is that natural spider silk exhibits a property called ‘supercontraction.’

For example, the extremely tough dragline silk spiders use as their lifeline contracts up to ~50% in length when exposed to water.

The protein material which Spiber initially developed, QMONOS (based on the Japanese word for spider web, kumonosu), comes from fibroin proteins found in dragline silk, and thus inherited this supercontraction property. As we considered how to prepare our materials for use in end products, we concluded it would be difficult to reduce this water-induced supercontraction effect to meet Goldwin’s exacting quality standards.

We therefore began from scratch, starting with fresh analysis of genes involved in natural fibroin production. We could thereby isolate and remove the amino acid layout responsible for the supercontraction effect.

We also implemented further modifications to the amino acid sequence, resulting in drastic increases in microbial productivity. Repeating this molecular optimization—mimicking natural evolution—while passing the improved materials through our proprietary spinning, weaving, and processing technologies, created a new protein textile material capable of maintaining its dimensions when wet. The new material used in the jacket’s shell layer has come a long way from the initial synthetic proteins based on natural spider silk. New structural proteins created in this way allow for design of material features according to application, and materials produced can have a wide variety of characteristics. We therefore decided to change the name for the structural protein material developed by Spiber from QMONOS, symbolizing the function and organism from which it was derived, to Brewed Protein™, a higher level concept representing the characteristics of the manufacturing process of fermentation by microorganisms.

Brewed Protein™ Features & Potential

Towards Next-Generation Key Raw Materials Without Reliance on Fossil Resources

The major characteristic of the structural protein Brewed Protein™ is that it does not rely on petroleum or other fossil resources as ingredients. It is produced through fermentation of plant-derived sugars (glucose and sucrose), using microorganisms. With needs for microplastic-free and animal-free products in the apparel sector, lightweight products in the transportation sector, and artificial hair and medical products, Brewed Protein materials, made with non-petroleum derived ingredients, show great potential for a wide variety of uses. It is considered a key next-generation material that will contribute to the development of a sustainable society.

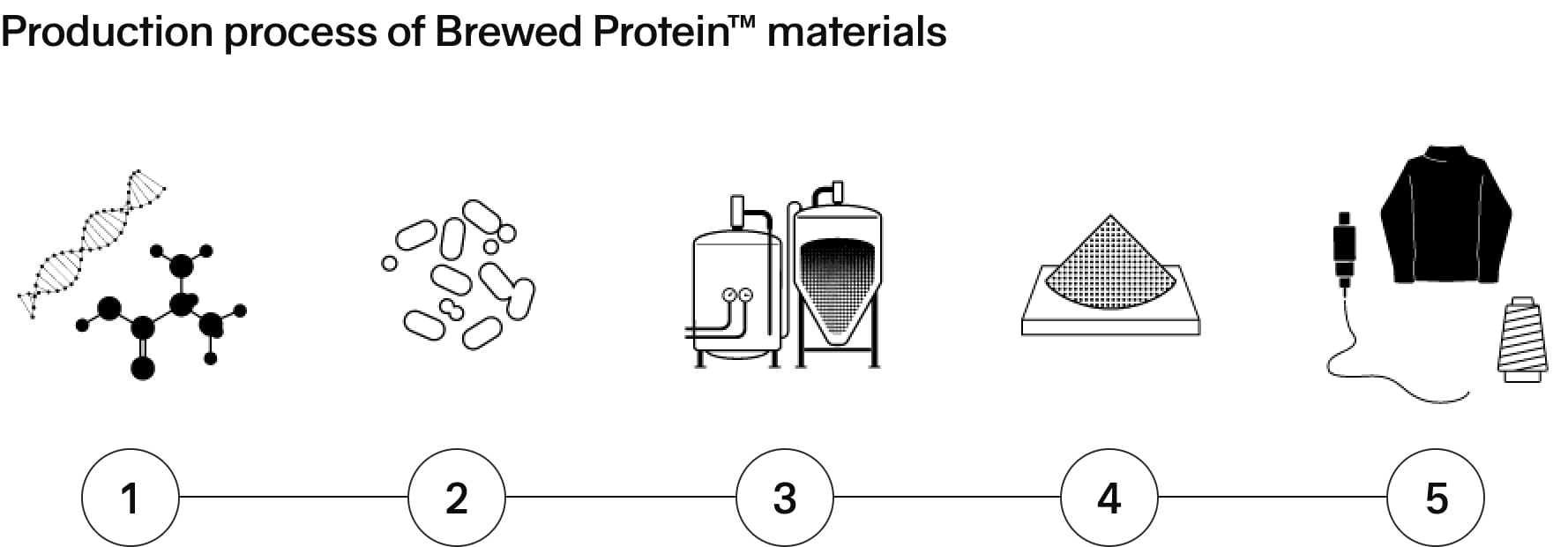

Brewed Protein™ Production Process

At Spiber, we begin by designing genes that code for the desired structural proteins (①). We introduce those genes into microorganisms engineered for high-level production of the protein(②). Raw materials such as sugars and minerals provide energy and nutrients for the microorganisms to produce proteins. In the Brewed Protein™ production process, these raw materials are prepared in large tanks, where microorganisms grow and multiply, and proteins are produced at high efficiency via fermentation (③). After fermentation comes the purification process, to separate target proteins from the microorganisms (④). Purified proteins are then dried and the resulting powder is processed into fibers, films and other forms (⑤).

Our First Product Developed From Brewed Protein™

T-Shirts that Contain a Message about Global Environmental Issues

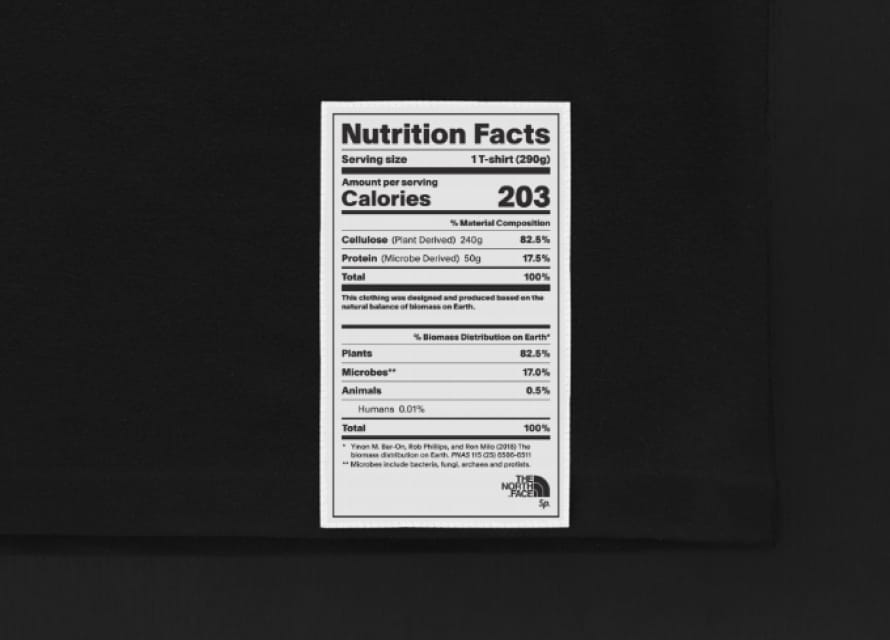

Released by The North Face in August 2019, the Planetary Equilibrium Tee was the first item sold featuring Spiber’s revolutionary new Brewed Protein™ materials.

The T-shirt’s name refers to the balance of living matter in the earth’s biosphere, and is a reminder of Spiber’s research and development mission—addressing global environmental issues. The t-shirt features a 82.5 to 17.5 blend of plant-based cellulose (cotton) and Spiber’s microbially-produced protein materials (Brewed Protein™). This symbolizes the proportion of plant to microbial life found on Earth, and demonstrates the potential for an animal-free manufacturing process. As far as possible, we produce resources from primary producers, that is, plants and energy-efficient microorganisms, to be compatible with the natural balance. We consider this a part of our Vision.

Our Second Product Developed From Brewed Protein™

An Outdoor Jacket Developed through Four Years of Overcoming Challenges

In December 2019, The North Face released the MOON PARKA®, their second item featuring Spiber’s Brewed Protein™ materials. The MOON PARKA® was conceived for use in a wide range of conditions, featuring an outermost layer of 100% Brewed Protein™ materials and inner layers of a waterproof/breathable laminate and 900 fill power CLEANDOWN® padding for exceptionally snug heat retention. The name MOON PARKA® was inspired by the term “moonshot,” referring to a great challenge that, despite the difficulties, can have enormous impact if achieved.

The T-shirt described above uses Brewed Protein™ as short fibers, whereas in MOON PARKA®, it is used as long fibers. This ability to tailor fiber length and other features of Brewed Protein™ materials demonstrates their suitability for a wide range of apparel applications.

Our Third Product Developed From Brewed Protein™

Blended with Versatile and Adaptable Animal Fibers

In November 2020, we introduced The Sweater, a garment made from a blend of wool and Brewed Protein™, under our original Goldwin brand.

Until now, humans have developed sweaters through technology and wisdom, such that they are now indispensable in winter. Yet its basic design has remained largely unchanged since the first sweater, a millennium ago. That it has become part of the culture and history of people worldwide is due to the versatile and adaptable animal fibers it can made from, and the knits that bring out the full potential of those fibers. The Sweater by Goldwin weaves a contemplation of the sweater’s origin with an application of future-facing technology.

It is only available in black, that contains all colors within itself. The Sweater knits together the distant past and the future in a single piece of black apparel. This single black item represents both the past and the future.

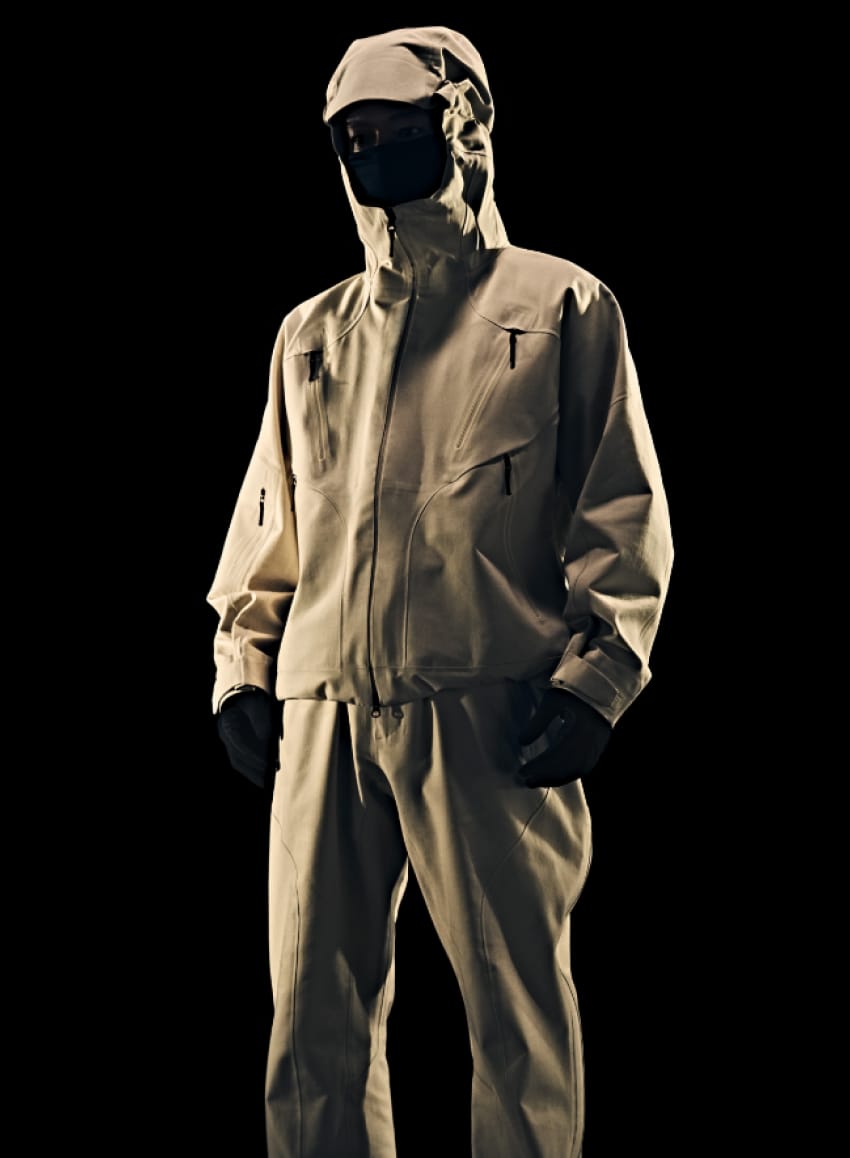

Our Fourth Product Developed From Brewed Protein™

Goldwin 0 Conceives of a Future with Both People and Nature

We began expanding Goldwin 0 in the fall of 2022.

The Goldwin 0 project conceives of a future for people and nature through collaboration with creators in diverse domains, including apparel, visual expression, music and spatial representation.

Goldwin 0 aims to develop men’s and women’s fashions with advanced functionality combining new technology, fabrics and other elements, adaptable to all scenarios, to wear in professional and private life.

We used raw ingredients that have less impact on the environment, for example, developing a jacket from Brewed Protein™, expressing the three key concepts of circulation, borderless, and co-creation, towards the realization of a circular society.

Our Fifth Product Developed From Brewed Protin™

Fleece Made from Structural Protein Material

In fall 2022, The North Face collaborated with eYe Junya Watanabe Man, the second brand of Junya Watanabe Man, by designer Junya Watanabe, to launch The Earth Hoodie fleece, made from structural protein Brewed Protein™.

Many fleeces presently worn in a wide variety of settings, from outdoor to casual, are made from synthetic fibers derived from petroleum, a non-renewable resource.

Furthermore, the synthetic fiber fluff from fleeces enters household wastewater through washing and is carried to rivers and the ocean, adding polluting microplastics that damage sea organisms and the ecosystem.

Because The Earth Hoodie is made from structural protein Brewed Protein™, developed using plant-derived biomass for its raw material, we hope it will help to lessen environmental burden through reduced reliance on microplastics.

The Potential For Brewed Protein™ In Sports Apparel

Aiming for Totally Cyclical Sports Apparel

At Goldwin Group, we aim to enhance environmental sustainability and to offer products that will benefit consumers safely and for the long-term. Consequently, we actively promote the development of products made from renewable raw materials that have less environmental impact.

In the near future, we expect to be able to use structural protein Brewed Protein™, which does not rely on petroleum, to replace the range of materials used in apparel construction, including exterior and interior materials, down, and fasteners. In addition, we also aim to create cyclical sports apparel, with our sights set on creating systems that can return apparel into raw materials to recycle into new clothing.

Because we love sports, we will continue to develop sustainable apparel incorporating functions whereby the wearer can give their best performance in a beautiful natural environment in the future.