Realization of a Circular Society Sustainability

Basic Concept

While the apparel industry performs an important role in people’s lives, the negative impacts on society and the environment of mass production, consumption, and disposal are increasingly severe. We must effectively use resources, such as by using renewable raw materials and extending product lives.

We are aiming to realize a circular society through zero fashion loss initiatives to eliminate waste, including waste reductions in our business activities and reuse of apparel that is no longer needed.

Key Environmental Issues

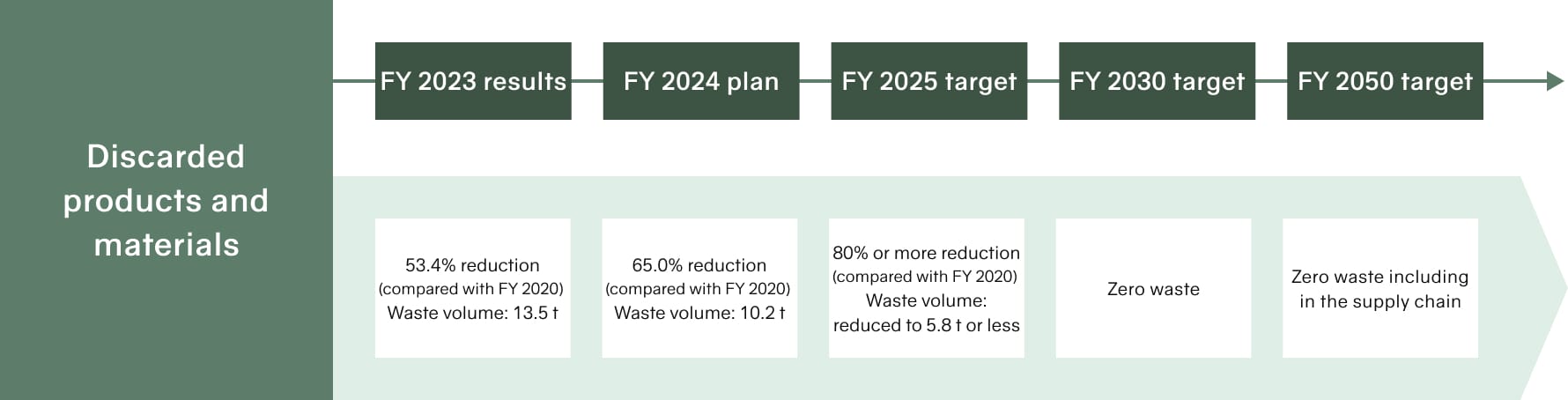

Until now, we have rigorously managed procurement and production plans and taken other steps to reduce material and product waste in our Group. To eliminate simple incineration and landfill disposal of waste throughout the supply chain, our medium-term management plan includes “Realization of a circular society” as a priority issue. We are promoting initiatives to achieve zero waste of materials and products across the supply chain, and in-store collection and reuse of apparel that is no longer needed, aiming to realize a circular society.

In addition, the secretariat of our EMS Committee, chaired by our President and Representative of Board, manages the actual amounts of products and materials disposed of each month, and promotes waste reduction. Progress is also reported at bi-annual Environmental Management Meetings.

Reducing Waste

Our Group’s volume of industrial waste was 63.7 tons in FY 2024. The volume increased due to relocation of the head office in May 2024 and consolidation of logistics warehouses, etc. Products and materials account for approximately 16% of our total waste, and we are striving to reduce fashion waste through efforts such as use of digital technology in design and reduction of fabric waste generated from the product manufacturing process. We will continue to consider measures to reduce and effectively use product and material waste, aiming to achieve zero waste. Efforts are underway to reduce and recycle plastic resources from product packaging and other areas.

Reducing Product Waste by Lowering Sales Loss Rate

A major environmental issue in the apparel industry is product waste due to excess supply. With the shift to an in-store digestion-based product supply business model from 2000, we commit to order flow management and strictly manage the total amount of procurement. Rapid inventory flow during the sales period has also helped us to reduce the sales loss rate to 1.4% in FY 2024.

Conservation of Water Resources

Goldwin Group is committed to the conservation of water resources, including reducing water consumption through using water sparingly, wastewater treatment, and proper management of wastewater quality. In terms of water supply, our Tokyo Head Office uses tap water, while our Toyama Office and Goldwin Logitem use groundwater. Total water usage in FY 2024 at our sites (Toyama Office and Goldwin Logitem) was 209,362 ㎥ of groundwater.

In addition, 11,055 ㎥ of domestic wastewater was discharged into the sewerage system, and no pollutants were observed.

| Unit | FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | ||

|---|---|---|---|---|---|---|---|

| Water Supply | Groundwater | ㎥ | 232,048 | 178,496 | 159,155 | 126,623 | 209,362 |

| Sewerage | ㎥ | 10,924 | 10,311 | 10,685 | 12,371 | 11,055 | |

Reduction of Paper Usage

Goldwin Group promotes paperless offices and is committed to reducing the amount of paper used in offices. We are working to use less copy paper such as by shifting to electronic materials and documents, introducing electronic systems for application processes, encouraging double-sided and multi-page printing, and promoting paperless meetings using notebook computers.

In FY 2024, 2,318 kg of copy paper was used in Tokyo region.

Initiative for collecting clothes at stores

With the aim of realizing a sustainable society by considering the environment together with consumers, we collect and recycle clothes that they no longer need. Through initiatives to recycle fiber products, we are promoting the realization of a circular society. Through initiatives to recycle fiber products, we are promoting the realization of a circular society.

Measures for the Careful Use of Resources

Initiatives for circular clothing business

Goldwin Group is also promoting initiatives to incorporate clothing into a circular model, for the careful use of our limited resources. We started recycling in collaboration with various partners in 2008, whereby we collect garments that are no longer needed regardless of the brand, quality and condition, and convert them to raw materials for new products.

In FY2024, 12,154 kg of clothing were collected. We placed recycle boxes at 163 stores across Japan (as of March 31, 2025), mainly at directly managed stores, to facilitate the collection of products from our customers. We also collect products at sports events, such as the Toyama Marathon and Kataller Toyama (professional soccer team) home matches, and facilitate recycling activities for a circular business in collaboration with our partners (JEPLAN, INC., Kawada Feather Co., Ltd.)

Repair Service to Encourage Long-Term Use

For some of the brands we carry, the Group provide repairs with a strict policy of “free repairs on items with material or manufacturing defects, and repairs on other cases for a reasonable price.”

We have established a permanent repair service counter at directly managed stores in the Yebisu Garden Place Center Plaza in Tokyo and Grand Front Osaka, also accept repair requests on our website. There has been no charge for the repair of Goldwin brand products, and the number of requests for repairs has increased from about 3,500 per year in 2004 to 23,887 in FY2024.

We anticipate that demand for product repairs will continue to increase, and in addition to expanding our repair system and responding to this increase in repairs, we aim to reduce the current four-week turn-around to two weeks by 2025.

Launch of “GREEN BATON” resale business

It is generally said that children outgrow their clothes in about two years, and according to our survey, approximately 40% of these clothes are discarded as garbage.

Since July 2022, under the sustainable label “GREEN BATON,” we have implemented an initiative to buy clothes that children have outgrown, and then repair or upcycle them before selling them as new products. Resold products are distinguished with a green zipper pull and name, resembling a relay baton, adding value to these unique, one-of-a-kind products.

In FY 2024, customers purchased a total of 1,802 products.

Future Issues

The amount of collected clothing is on the rise, and we have also continuously engaged in the repair and resale business “GREEN BATON.” To achieve zero waste in our supply chain by FY 2050, our future issues are understanding and reducing waste volumes not only at our company but also in the supply chain and considering measures for reusing what is otherwise disposed of.