Supply Chain Management Sustainability

Basic Concept

As the supply chain expands around the world today, striving to realize a sustainable society throughout it beyond the scope of a company’s own group is an important social responsibility. The Goldwin Group established the Goldwin Group Procurement Policy, which positions mutual benefit with suppliers at its foundation, to promote sustainable and responsible procurement that takes the environment, society, and human rights into consideration with high ethical standards.

Goldwin Group Procurement Policy

Goldwin Group (hereinafter referred to as “The Group”) aims to realize a sustainable society through our business activities based on our corporate philosophy “to realize a fulfilling and healthy lifestyle through sports”.

With coexistence and co-prosperity with our suppliers as the basis, we established the Goldwin Group Procurement Policy in order to promote sustainable and responsible procurement which considers the environment, society and human rights with high ethical standards.

1.Considerations for the environment, society and human rights

- To achieve prosperity in harmony with nature, we provide environmentally friendly products and services based on The Group’s “Basic Principles of Environmental Protection” and “Goldwin’s Environmental Policies”.

- We respect human rights of employees and local communities in accordance with the “Goldwin Group Policy on Human Rights”.

- With continuous improvements, we promote procurements with respect to working environment and occupational health and safety.

- Through our corporate activities, we live in harmony with local communities and promote social contribution.

- We ensure traceability of materials and processes within procurement.

- Considering the impact on society, we purchase raw materials that are not involved in conflicts or crimes.

- We respect The Five Freedoms for Animals and use materials that are treated ethically.

2.Ensuring transparency and fairness

- We conduct our procurement with integrity, respecting not only the laws and regulations of each country, but also the international code of conduct and ethics.

- When selecting suppliers, in addition to ensuring quality, cost, and delivery, activities regarding the environment, society and human rights are evaluated fairly and impartially to promote honest transactions.

- We manage confidential and personal information obtained through procurement securely. We will not conduct procurements that infringe intellectual property of third parties.

3.Ensuring quality and safety

- To provide valuable products and services, we will work with suppliers to maintain and improve the quality and safety.

Goldwin Group Supplier Code of Conduct

The Group established the Goldwin Group Supplier Code of Conduct (Japanese and English versions) as a set of fundamental principles for suppliers to be followed when conducting transactions with the Group and seeks their understanding of and compliance with the Code. In FY 2023, we revised the Code to clarify the conduct norms that all suppliers are required to follow (including labor and human rights, the environment, and safety and hygiene) as well as management structures (including management systems, grievance mechanisms, and disclosures). In FY 2025, we will continue to seek the understanding of suppliers regarding the revised Code, re-request that suppliers sign an agreement, and contribute to the development of a sustainable society by conducting supply chain management that emphasizes transparency.

| Category | Main Items | |

|---|---|---|

| 1 | Corporate Governance | Create structures to fulfill social responsibilities and achieve business continuity as a company |

| 2 | Legal Compliance | In addition to complying with relevant laws and regulations, conduct business ethically |

| 3 | Labor and Human Rights | Comply with the Goldwin Group Policy on Human Rights and comply with prohibitions of child labor and forced labor and other requirements |

| 4 | Safety and Hygiene | Maintain environments where employees can work in a safe, hygienic, and healthy manner |

| 5 | Environment | Collaborate in accordance with the Group’s environmental strategy and strive to minimize environmental impacts |

| 6 | Fair Corporate Activities | Do not engage in illegal acts and conduct corporate activities based on fair and free competition |

| 7 | Responsible Procurement | Conduct procurement with consideration for human rights, the environment, and animal welfare and endeavor to ensure traceability |

| 8 | Communities | Reduce negative impacts on local communities and work toward the development of local communities |

| 9 | Monitoring Compliance | Cooperate with retention of records and audits to confirm the status of compliance with the Code of Conduct; if any instances of nonconformity are discovered, work to correct them |

| 10 | Product Quality and Safety | Comply with the Goldwin Products Quality Standard to produce safe and secure products; when problems occur, respond appropriately |

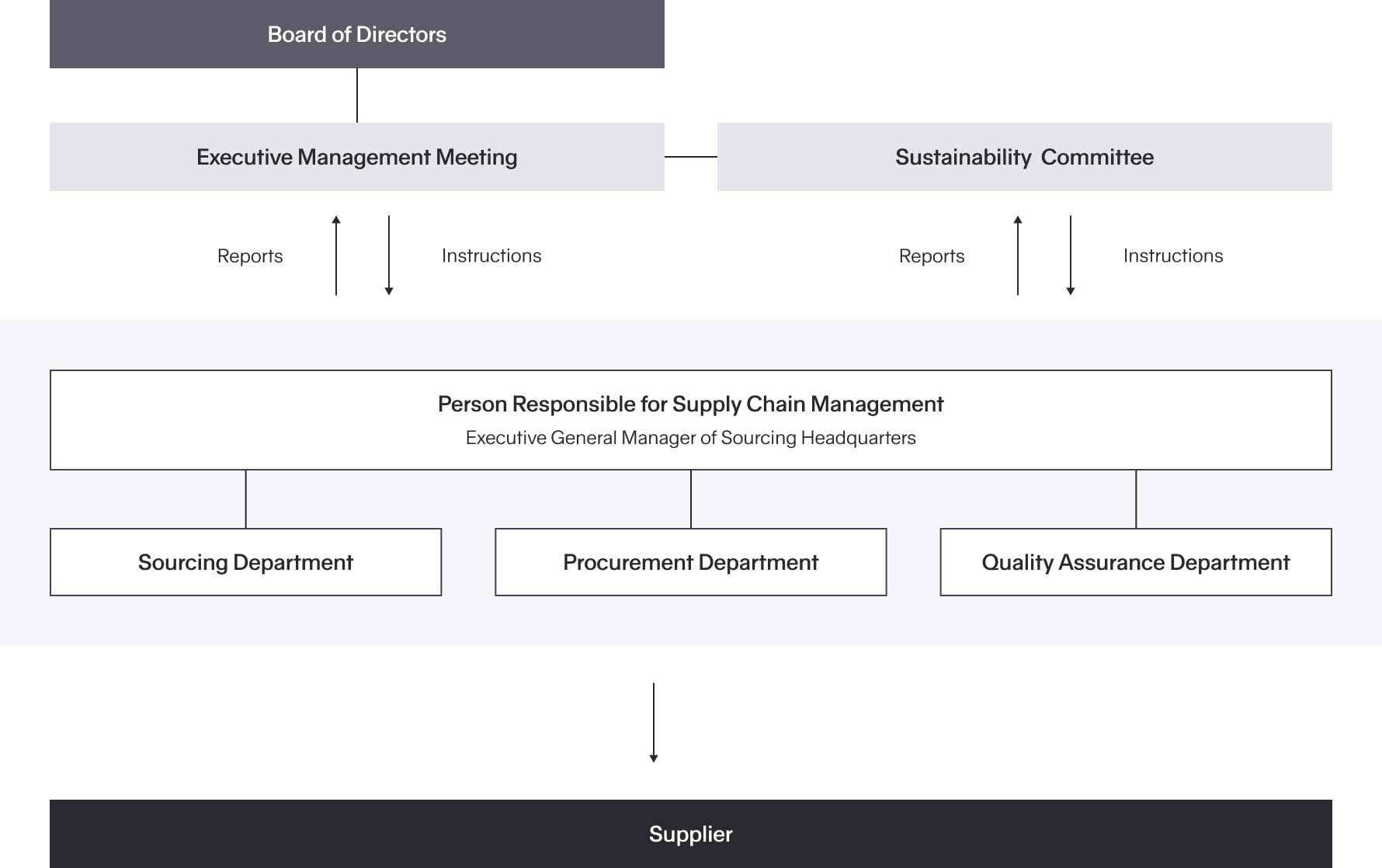

Promotion Framework and Person Responsible

We have built a supply chain management system led by the Sourcing Department and Quality Assurance Department, with the Executive General Manager of the Sourcing Headquarters having responsibility. We maintain communications with suppliers in Japan and overseas, and ask for their understanding and cooperation with Group policies in the presence of product and material procurement personnel. Activities are reported to the Sustainability Committee and the Executive Management Meeting, with oversight and guidance received from the Board of Directors through the Executive Management Meeting.

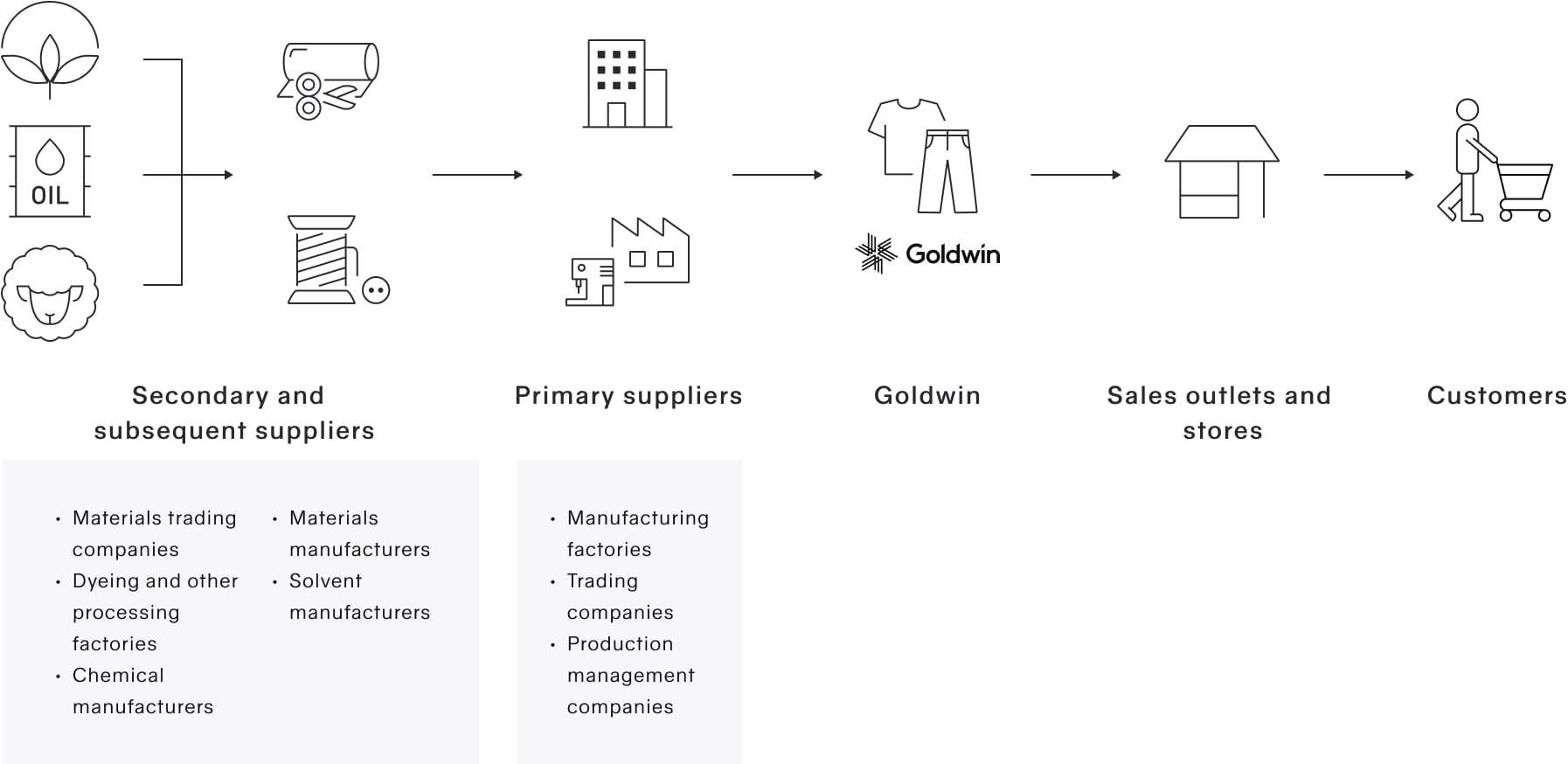

Goldwin’s Supply Chain

We conduct direct and indirect procurement activities with a wide range of suppliers inside and outside Japan.

We take a broad view of the Group supply chain as encompassing primary suppliers that deliver finished products to us and secondary and subsequent suppliers that supply materials, chemical substances and raw materials for our products through primary suppliers.

Our primary suppliers are manufacturing factories for Group products and trading companies and production management companies involved in the manufacturing. Along with quality guidance and other direct communication, we have also started conducting on-site audits of manufacturing factories since FY 2021. Approximately 90% of these manufacturing factories (on an order value basis) are located outside Japan.

Secondary suppliers refer to materials manufacturers that manufacture materials (fabrics, auxiliary materials, etc.) after raw materials procurement, dyeing, and other processing, as well as trading companies.

We require that our primary suppliers and main secondary suppliers sign an agreement for the Goldwin Group Supplier Code of Conduct and the Goldwin Group Restricted Substance Management Regulations. We signed an agreement with suppliers with whom we had transactions in FY 2023 and are conducting self-assessment questionnaires (SAQ).

Public Disclosure of Production Factory List

To build a sound supply chain, the Group collaborates with suppliers in initiatives to improve product quality and address issues in human rights, the environment, and safety. Since FY 2025, we publicly disclose the list of production factories among our primary suppliers that manufacture our products, with the aim of increasing supply chain transparency and fulfilling our social responsibilities.

Selection of New Suppliers

We only begin transactions after confirming that all documents have been received and that the supplier is found to be conforming through an SAQ. In FY 2024, we started dealing with 78 new suppliers (54 factories, 21 management companies, and 3 material companies).

Documents required prior to entering a supplier contract

- Agreement for the Goldwin Group Supplier Code of Conduct

- Corporate data sheet

- Company confirmation documents (business license, factory registry, etc.)

- Self-assessment Questionnaire (SAQ)

- List of affiliated companies and subcontractors

- Agreement for the Goldwin Group Restricted Substance Management Regulations

- Hazardous materials management survey

CSR-Based Procurement

To build a healthy supply chain, improve product quality, and strengthen initiatives for human rights, the environment, and safety, etc. we ask suppliers to update the necessary paperwork each year. Since FY 2021, we have been conducting SAQ and on-site audits by third-party auditors to monitor compliance with the legal, social, and ethical requirements defined in the Goldwin Group Supplier Code of Conduct.

SAQ Implementation

The Group sends SAQ to suppliers simultaneously once a year, asking them to check the promotion status of their own CSR activities. The Group then checks the results of the responses, and any suppliers whose responses indicate a risk are asked to make improvements on a case-by-case basis. In FY2024, 408 companies were subject to SAQ, and responses were collected from 407 companies in total.

SAQ categories

- Corporate Governance

- Legal Compliance

- Labor and Human Rights

- Safety and Hygiene

- Environment

- Responsible Procurement

- Monitoring Compliance

- Product Quality and Safety

In FY 2023, we expanded the scope of SAQ to include not only manufacturing factories, but also management companies and trading companies of primary suppliers, as well as some major materials companies that are secondary suppliers. In addition, in conjunction with the revision of the Goldwin Group Supplier Code of Conduct in FY 2023, we also updated the content ofSAQ to score and manage the promotion status of CSR at suppliers. As the FY 2024 audit results show, the status of “Environment” initiatives at suppliers is 74%, indicating that there are more issues involving the environment to be addressed than in other categories. Based on these results, we will strengthen our cooperation to promote CSR activities at suppliers.

In addition to managing the exhaustive promotion status of CSR activities, we have also defined high-risk categories separately for SAQ, and based on the results of responses, “items of concern” are fed back to suppliers. For the “items of concern,” we primarily made requests for improvement and monitored progress by communicating individually with relevant suppliers. In FY 2024, “items of concern” were identified at 125 suppliers. These identifications have decreased from the previous year, and increasing awareness of risks presents an opportunity to promote voluntary corrective actions.

407 companies

207 cases

On-site Audits

The Group requests suppliers to conduct social responsibility audits and on-site audits. As part of our company’s standards, we require suppliers to comply with international audit programs such as SMETA and BSCI and some manufacturing factories to undergo on-site inspections by our employees.

In FY 2024, we conducted on-site audits at 215 manufacturing factories, comprising initial audits at 32 companies and renewal audits at 183 companies, and we requested corrective actions for all issues identified. If the content of an issue was deemed to be of high priority, we requested the submission of a corrective action plan and completed implementation up to the confirmation of the status of the corrective action after the audit. Furthermore, in FY 2024, we conducted follow-up on-site visits primarily to suppliers subject to corrective action plans to verify the status of their corrective measures. At the same time, we ensured they understood that failure to address particularly high risk items by the next visit could result in the suspension of transactions. Creating these opportunities for direct dialogue became a chance for both the Group and our suppliers to deepen mutual understanding.

The main issues identified in FY 2024 include “Safety and Hygiene” at 54% (e.g. no safety devices installed on sewing machines, no risk assessment of work safety) and “Labor and Human Rights at 31% (e.g. exceeding legal working hours, lack of enrollment in social insurance system), with these two items accounting for 85% of the total. Additionally, among the identified issues, for identifications of management items classified as Zero Tolerance (high risk of non-compliance) and Critical (requiring immediate corrective action), which we deem particularly high risk, there were zero cases of Zero Tolerance and 198 cases of Critical in FY 2024. For Critical issues, corrective actions were verified through corrective action plans.

Additionally, we conducted follow-up visits to four factories deemed high risk due to Critical issues and confirmed corrective actions that could not be fully conveyed in writing which fostered mutual understanding.From the next fiscal year onwards, we will continue to conduct on-site audits at all manufacturing factories and confirm the status of corrective actions for issues, leading to continuous improvement of the factory management CSR framework.

Communication with Suppliers

Our business would not be possible without the cooperation of suppliers that produce products and deliver products and materials to us. We broadly share our principles for promoting sustainability through business activities with our supply chain, and focus on communication with suppliers on an individual basis to build a cooperative framework based on mutual trust.

Goldwin Supplier Summit

Once every two years, Goldwin hosts a two-day supplier summit—a meeting that brings together its major suppliers (trading companies, materials manufacturers, etc.) under the one roof. Our representative directors and general managers of each business division also participate, and on the first day, we present our management and business policies. On the second day, we build partnerships through communication, such as by actually using Goldwin products while trekking or trying marine sports.

In FY 2024, 42 representatives from 28 suppliers participated in the summit. First, in addition to learning our company’s policies, they learned about the initiatives under the Group’s Comprehensive Partnership Agreement with the town Taketomi in the Yaeyama District of Okinawa Prefecture, as well as the rich natural environment, unique traditional culture, and its preservation. On the second day, they went out into nature and experienced activities like trekking, kayaking, and cycling.

Engagement with Suppliers

In addition to the Goldwin Supplier Summit, we actively provide opportunities for exchanging opinions as a form of engagement with suppliers. We ask both suppliers in Japan and overseas for their opinions on our initiatives to share awareness and deepen mutual understanding. In addition, our staff visit supplier factories that are deemed to require support in the course of audits to confirm conditions that are difficult to ascertain from reports and provide guidance on improvement measures.

FY 2024 performance

- Respective awareness sharing and exchange of opinions with major trading companies and management companies that manage manufacturing factories: 4 companies

- Respective awareness sharing and exchange of opinions with small- and medium-sized management companies that manage manufacturing factories: 4 companies

- Audit review of managed factories with major trading companies (sharing results and countermeasures): 7 companies

- Post-audit follow-up visits to domestic factories (sharing issues and confirming corrective action status): 4 companies

- Human rights due diligence on factories with foreign technical intern trainees (suggestion to share the burden of recruitment fees): 6 companies, 1 organization

Briefings for Business Partners

Goldwin holds briefing sessions for its suppliers on its CSR framework for the supply chain. In the briefing, suppliers are asked for their understanding and compliance with the Code of Conduct for Goldwin Suppliers, and we explain the background and specific revisions to the Code, as well as practical aspects of the paperwork that needs to be submitted.

In FY 2024, like in the previous year, we distributed periodically updated explanation videos focusing on this period’s revisions to 476 continuing suppliers (as of April 2024), including manufacturing factories, trading companies, production management companies, and raw material-related companies. Additionally, we conducted Restricted Substance Management Briefings in person for eight major business partners and CSR Audit Review Meetings (including Goldwin audit evaluation briefings) for another eight companies were not a part of the restricted substances management briefings.

Meetings with Main Suppliers (Trading Companies)

Goldwin holds separate regular monthly meetings with each of its major suppliers (trading companies). The meetings are a place to exchange information on quality, cost, delivery schedules, and other matters as well as to discuss issues that arise from time to time and resolve them together. Engaging in communication helps deepen our cooperation and build better partnerships.

Internal Education

The Group provides regular education to internal persons in charge of procurement to enhance our CSR framework for the supply chain.

In FY 2024, we conducted study sessions on restricted substance management regulations for employees in business divisions and the Procurement Department, aiming to restructure our restricted substance management system. We conducted a total of 11 sessions at our business locations in Tokyo and Toyama, with approximately 500 participants.

We will continue to carefully explain the Code of Conduct for Goldwin Group Suppliers, its content, and approaches for promoting the current system, and share information so that we can respond appropriately when performing our role as a point of contact with suppliers.

Subcontract Act Training

Internal training is regularly provided on the Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors (Subcontract Act), which is a law that helps ensure that transactions are fair. In addition to explaining things like the purpose of the Subcontract Act, as well as relevant conditions and obligations of procuring companies, we discuss information that is required on order forms to ensure compliance with the act when company employees place orders.

Future Issues

The Goldwin Group will continue to deepen collaborations with suppliers to fulfill its social responsibility through the entire supply chain.

From FY 2025 and onward, we will continue to promote responsible procurement activities by reinforcing engagement with suppliers and enhancing internal education. In particular, in addition to creating more opportunities and furthering the training of investigators to provide detailed explanations to suppliers through face-to-face meetings, we will strengthen our collaborations with suppliers to reduce environmental impact across the entire supply chain. We will continue to work toward building a highly transparent supply chain while seeking the understanding and cooperation of our suppliers.