Realization of a Carbon-free Society Sustainability

Basic Concept

The apparel industry is said to be an industry with extremely high CO₂ emissions. Global warming is an urgent problem that requires a proactive response to achieve the 1.5% target adopted in the Paris Agreement. Our Group is committed to reducing greenhouse gas emissions through business activities that have a low environmental impact by using minimal resources and energy. Going forward, we aim to achieve carbon neutrality by reducing emissions at our directly managed stores, procuring raw materials that do not rely on fossil fuels through strengthening cooperation with suppliers, and reviewing our manufacturing processes.

Key Environmental Issues

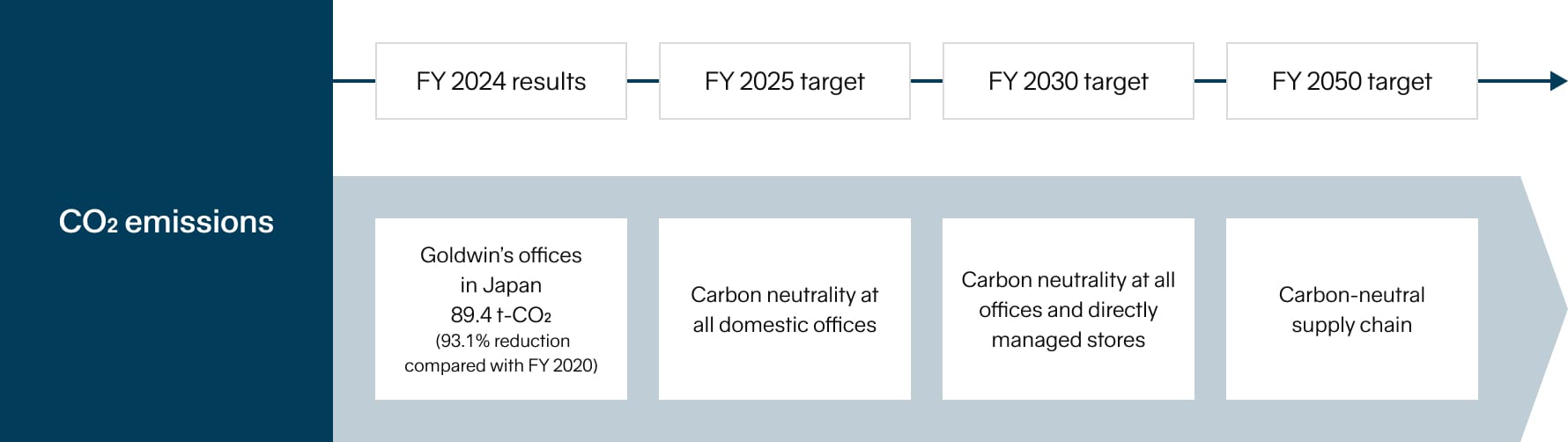

We have been working to reduce energy use and CO₂ emissions at our main offices since before. To further boost these efforts and to reduce CO₂ emissions across the supply chain, we have included “Realization of a carbon-free society” as a key issue in our medium-term management plan. We will strengthen cooperation with suppliers, aiming to procure raw materials that do not come from fossil fuel sources, and to achieve carbon neutrality. Furthermore, to achieve the Paris Agreement’s goal of “holding global temperature increase to 1.5°C above pre-industrial levels,” we have obtained Science Based Targets initiative (SBTi) certification for our targets and are working to reduce greenhouse gas emissions.

We are also promoting initiatives towards the realization of a carbon-free society, centered on our EMS Committee, chaired by our President and Representative of Board. The EMS Committee manages actual greenhouse gas emissions of each of our offices every month and strives to reduce these emissions. Progress is also reported at bi-annual Environmental Management Meetings.

Greenhouse Gas Emission Reductions

The Goldwin Group continues to actively reduce greenhouse gas emissions. Greenhouse gas emissions from domestic business locations in FY 2024 totaled 89 t-CO₂, while emissions from directly managed stores totaled 2,810 t-CO₂.

Total emissions including Scope 1, 2, and 3 decreased by 50,029 t-CO₂ compared to the previous fiscal year, finishing at 212,835 t-CO₂.

Moving forward, we will further strengthen our efforts to reduce emissions based on these calculations. Specifically, in addition to Scope 1 emissions directly emitted by our company, we will reduce Scope 2 emissions by converting our directly managed stores to renewable energy and utilizing non-fossil fuel certificates. Furthermore, while referencing the carbon footprint calculations for our products and clarifying key reduction points, we will also strengthen our efforts to reduce Scope 3 Category 1 emissions, which account for a significant portion of our greenhouse gas emissions, by developing products with lower CO₂ emissions and enhancing collaborations with suppliers.

| Scope 1・2・3 | 212,835 |

|---|---|

| Scope1 | 286 |

| Scope2 | 2,613 |

| Scope3 | 209,936 |

| Category 1 | 201,971 |

| Category 3 | 739 |

| Category 4 | 3,973 |

| Category 5 | 49 |

| Category 6 | 379 |

| Category 7 | 882 |

| Category 12 | 1,943 |

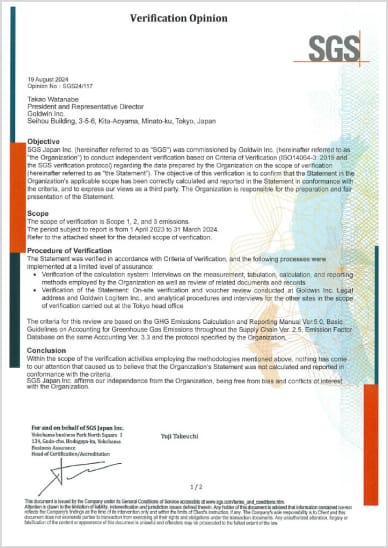

Undergoing third-party verification for greenhouse gas (GHG) emissions

To enhance the reliability of our greenhouse gas (GHG) emissions calculation, we underwent third-party verification from SGS Japan Inc. and announced the verification results.

We will continue to promote initiatives to reduce CO₂ toward the realization of a carbon-free society and properly understand and manage the environmental impact associated with our business activities. We will also provide our stakeholders with accurate information in an easy-to-understand manner and accelerate initiatives to reduce environmental impact.

Greenhouse Gas Emitted from Procurement Logistics

The Goldwin Group is working to identify Scope 3 Category 4 greenhouse gas emissions associated with transportation and delivery. For the 2,832 t-CO₂ emitted through procurement activities in FY 2024, we purchased carbon credits in the next year in FY 2025 to offset it. We are also actively pursuing measures contributing to decarbonization, such as reusing packaging materials and promoting mobility transition in transportation. We will continue to examine and implement concrete measures aimed at reducing emissions.

Calculating the Carbon Footprint of Products

The Group is working to calculate our carbon footprint of products with the goal of reducing Scope 3 Category 1 emissions (purchased goods and services), which account for the majority of our greenhouse gas emissions.

In FY 2024, we participated in the Ministry of the Environment’s “FY2024 Model Project for carbon footprint of products and services. ” We calculated the carbon footprint of the Baltoro Light Jacket (2024 Fall/Winter model), a representative product of our outdoor apparel brand THE NORTH FACE.

The results revealed that emissions during the raw material procurement stage account for approximately 80% of the total emissions for this product, identifying that reducing emissions at the material stage, particularly for fabrics, is a major issue.

Based on this knowledge, as part of our efforts to reduce greenhouse gas emissions, the 2025 Fall/Winter model of the Baltoro Light Jacket uses recycled nylon in its outer fabric. Compared to using fossil-derived materials, this achieves a reduction of approximately 1.8 kg of CO₂ emissions throughout the entire process from raw materials to manufacturing.

We will continue to strengthen our collaborations with suppliers and promote measures that reduce emissions from the raw materials stage.

Furthermore, we will expand carbon footprint calculations to cover a broader range of the Group’s products, increasing our understanding of the situation and enhancing reduction strategies.

Details of the product

Product name

Baltro Light Jacket (Unisex)

Size

L

Material

<Outer fabric> – Front: 100% nylon, Back: ePE

<Lining> 100% nylon

<Filling> 72% down, 20% rayon, 8% feather

Calculation unit

1 piece

Structural parts in calculation

Product body, storage bag, brand name, fabric label, price tag, product packaging plastic bag, etc.

| Raw materials procurement | 25.0 |

|---|---|

| Production | 0.1 |

| Distribution/sales | 1.4 |

| Use | 1.8 |

| Disposal | 3.1 |

| Total amount | 31.4 |

Reduction of Energy Use

The Goldwin Group continues to reduce greenhouse gas emissions.

The total energy consumption at major domestic locations in FY 2024 was 29,781 GJ, a reduction of 4,766 GJ from FY 2023, but the combined total energy consumption of major domestic locations and directly managed stores increased by 2,285 GJ. This increase is due to higher consumption of city gas used for powering electricity at directly managed stores and for air conditioning at tenant stores in shopping malls. The use of both gasoline and diesel fuel decreased thanks to our efforts to promote the use of public transportation. We will continue our energy conservation efforts and work towards reductions in FY 2025.

| Unit | FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | ||

|---|---|---|---|---|---|---|---|

| Electricity | 1,000 kWh | 3,501 | 3,502 | 3,473 | 8,548 | 8,773 | |

| City gas | For onsite facilities | 1,000 m3 | 3.192 | 2.197 | 3.759 | 118.803 | 185.891 |

| LPG | For onsite facilities | t | 6.9 | 6.7 | 5.8 | 4.7 | 4.7 |

| Heavy oil A | ㎘ | 50.8 | 52.0 | 18.4 | 0 | 0 | |

| Gasoline | For vehicles | ㎘ | 11.0 | 18.9 | 20.3 | 18.6 | 16.2 |

| Diesel oil | For vehicles | ㎘ | 0.980 | 0.862 | 4.492 | 3.571 | |

| Total energy | GJ | 37,765.5 | 37,979.9 | 36,372.2 | 82,310 | 84,595 | |

* Including results at stores, starting from FY 2023

Conversion to Renewable Energy

To reduce greenhouse gas emissions, our Group is shifting to renewable energy sources for the electricity we use. As part of these efforts, we have installed independent power generation systems using solar panels at our business premises in the Toyama region.

In FY 2024, electricity consumption increased due to expanded business activities and revisions to the calculation method for air conditioning usage in directly managed tenant stores. Nevertheless, the ratio of renewable energy use increased by 2.3 % from the previous year to reach 59.3%, indicating steady progress in its transition. Going forward, we will continue to visualize the situation and refine calculation methods while steadily transitioning to renewable energy.

* Including results at stores, starting from FY 2023

Proper Management of Chlorofluorocarbons (CFC)

Goldwin Group manages chlorofluorocarbon (CFC) used to fill air-conditioning units in accordance with standards set under the Act on Rational Use and Appropriate Management of Fluorocarbons. No CFC leaks were detected in FY 2024. We will continue to comply with laws and strive to reduce CFC emissions.

Future Issues

In FY 2024, we exceeded our planned reduction targets for greenhouse gas emissions at domestic business locations. At directly managed stores that can individually select its source of electricity, we are utilizing this strength to gradually switch to renewable energy. Meanwhile, at tenant stores where the owner’s policy significantly impacts our ability to switch to renewable energy, we will strengthen dialogue with owners to advance decarbonization efforts together. We will continue to strive for precise measurement of emissions, visualize emissions across our entire supply chain, including business locations and directly managed stores, and accelerate their reduction based on our medium- to long-term plans.