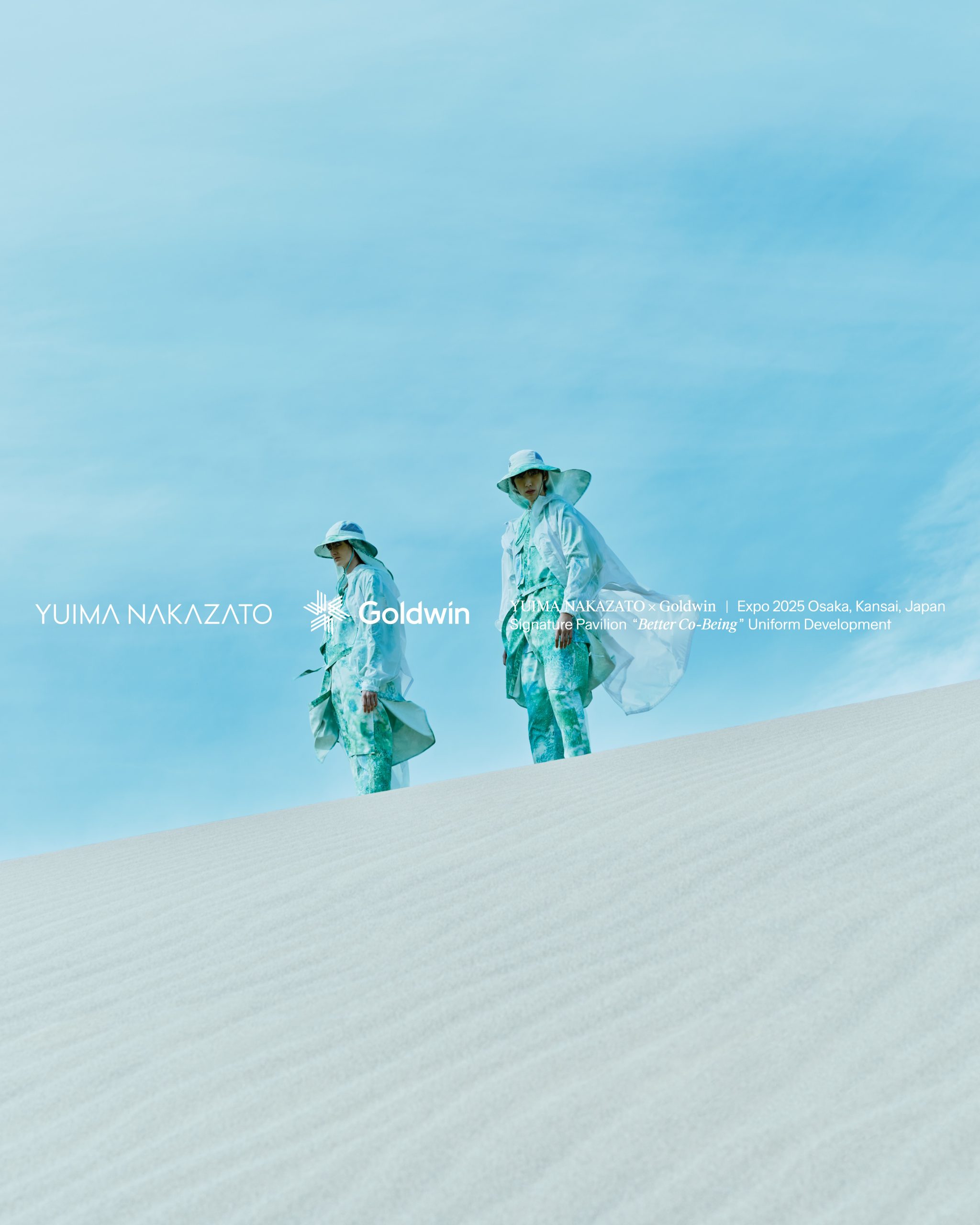

At Expo 2025 Osaka, Kansai, Japan organized by the Japan Association for the 2025 World Exposition, Goldwin Inc. (Headquarters: Minato-ku, Tokyo; President and Representative Director: Takao Watanabe) will take part in its Signature Pavilion “Better Co-Being® (Designing Future Society for Our Lives),” served by Hiroaki Miyata, Professor, Keio University School of Medicine as a thematic project producer, as a supplier and will plan, design and produce the pavilion’s attendant staff uniforms together with fashion designer Yuima Nakazato.

The Signature Pavilion’s “Better Co-Being” slogan refers to the idea of moving forward together and thinking together, ensuring harmony between each individual’s diverse fulfillment and society’s sustainability into the future. Replacing the “well” of “well-being,” which focuses on the present, with “Better” to imply the future, and combining it with “Co-being,” which means living together, the slogan signifies the idea that sustainability in the future and each individual’s diverse fulfillment are in harmony.

The “Better Co-Being®” Signature Pavilion has no rooves or walls and stands in unity with the “Forest of Tranquility” at the heart of the Expo’s venue. This setup means that attendant staff will need to ensure that guests from around the world will be able to enjoy their visits to the pavilion in an outdoor setting, be it rainy or windy. As Japan’s summers get increasingly severe with climate change, temperatures outdoors soar almost to life-threatening levels and are bringing torrential (localized) rain more frequently. In collaborating with fashion designer Yuima Nakazato for the first time to produce the uniforms, adequate formality was an essential factor, as was the functionality that would enable attendants to comfortably spend many hours outdoors.

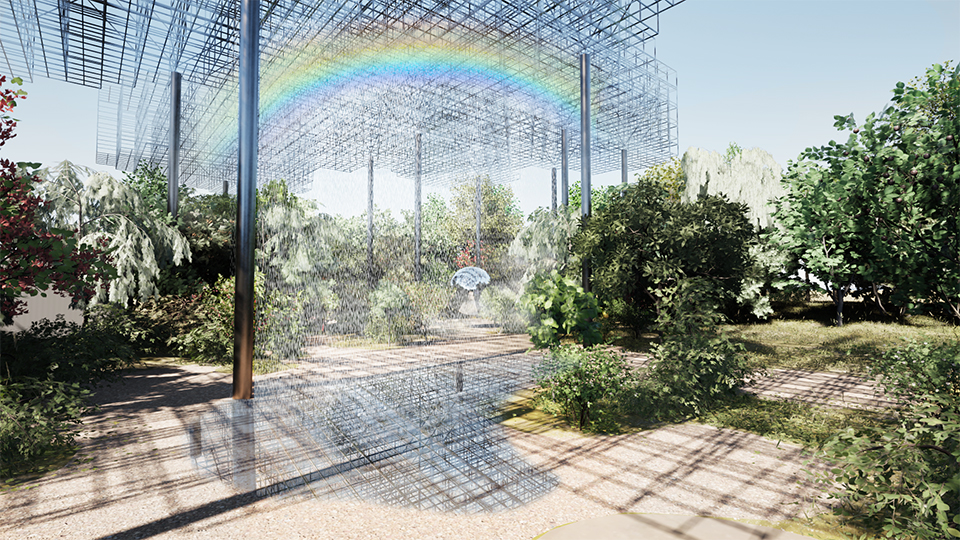

■“Better Co-Being®” Signature Pavilion (Designing Future Society for Our Lives)”

The “Better Co-Being®” Signature Pavilion has no rooves or walls and stands in unity with the Forest of Tranquility, which is at the heart of the expo venue (designed by SANAA with a total area of 1,634.99㎡). In this space, the essence of technology that transforms civilizations is seen as “resonance,” and questions about people-to-people, people-to-world, and people-to-future will be shared in this space that dissolves boundaries. Through art-based experiences, visitors will move forward together in harmony between each individual’s diverse fulfillment and a sustainable future and think about the future together.

To find out more about the pavilion, click: https://co-being.jp/expo2025/

■Design of attendant staff uniforms

If you wish to use the image visual of this uniform (including on page 1) please print ©YUIMA NAKAZATO & Goldwin Inc. alongside.

■Design concept in the words of Yuima Nakazato

“Inspired by how sunlight shows many faces according to time of the day and place, I wanted to create clothes that could be worn and shaped in infinitely many ways according to the wearer and the environment. I would like to include the word impermanence in the title of this uniform to reflect how every object keeps changing.”

Clothes presented with the pavilion’s vision for the future

The pavilion’s concept, “Better Co-Being®,” suggests the direction the world could take. What kind of clothes could embody such a concept? Countless conversations with Miyata revealed that “light” is a keyword. The kind of light that shines in the dynamism of life, the way living creatures respond to sunlight.

One summer in Southern France, I saw intense sunlight shining through the leaves. It reminded me that sunlight not only gives life to living creatures but also changes its face in countless ways, depending on the hour of the day and location. I knew then that this was exactly how I had wanted to present light and wanted to express this in the fabric of the “Better Co-Being®” attendant staff uniform.

I merged the photograph of the sunlight I saw digitally with a dotted abstract image of light and enlarged the combined image, repeating the image randomly with AI imaging technology. I then had the image printed on a textile with the most advanced printing technology(*), designing it in such a way that every item would have a unique pattern, varied by where the textile would get cut. Even if multiple uniforms are produced, every uniform would have a different pattern and create an individuality that suggests the diverse fulfillment of each individual as found in the pavilion’s concept.

Various unique features

Browsing Goldwin’s archives, I wished to include an Eastern identity in the required details and patterns.

I designed a unique placket for the front of the shirt and included a special feature to warrant breathability as much as possible, especially as the uniform will be worn in extreme heat. Inspired by the sliding paper doors from traditional Japanese architecture, I aimed for a structure that would take away the divide between the inside and outside of the uniform, with fasteners that can open the sides widely from underneath the sleeves to allow a breeze to pass through the wearer’s body dynamically.

The sleeves can also be rolled up to make the uniform sleeveless, presenting an option of reducing the entire surface area as much as possible. The wearer can adjust the fasteners to create various silhouettes according to their preference. Further, the waist belt was inspired from Kimono belts and can be worn at variable heights to change the shape in many ways according to the wearer’s liking or body shape.

※Uses Seiko Epson’s digital textile printer, “Monna Lisa,” and pigment ink. It uses 96% less water than analog textile printing and contributes to reducing waste by printing only the required amount when needed.

Epson Webpage: https://www.epson.jp/products/textile/

■Planned, developed and produced by Goldwin

Goldwin planned, developed and produced a uniform suitable for the outdoor pavilion, leveraging the expertise and technology we have cultivated over many years as a sports and outdoor apparel manufacturer. Our R&D facility at our oyama headquarters “Goldwin Tech Lab,” together with Yuima Nakazato played a central role in the project, aiming to create a uniform that would be comfortable for the attendant staff to wear, and that could be worn in a variety of ways to suit each individual’s personality and preferences in terms of design, functionality and diversity.

Developed a new heat-proof material

Our R&D facility “Goldwin Tech Lab” worked with a material manufacturer to develop a new textile thatwould prote ct the wearer from outdoor heat in the summer, focusing on the textile’s sun-reflecting ratio.

A new material was perfected for both the chemical-fiber shirt and for the cotton T-shirt, which were processed with special technologies to raise the UV protection and sunlight reflection rates. The textile was eventually featured in the uniform’s jacket, shirts and pants. This new heat-proof material is also environmentally friendly, being a 76%-recycled full dull textile made from used PET bottles collected in Japan.

Developed environmentally friendly textile graphics with AI and 3D digital technologies

An AI technology was used to develop textile patterns, and Goldwin Tech Lab’s 3D digital technology was used to develop and evaluate the graphics’ size and placement.

It is hard to turn delicate and fine textiles into seamless printing data, and more seams get wasted from pitches as patterns are repeated. To be more environmentally friendly, we have been developing seamless printing data with AI technology, creating patterns that are not bound by pitches. The AI technology was applied once again to develop this new textile, reducing waste. We also applied 3D digital technology and digitally created samples to reduce the effort associated with conventional textile development, as well as sample resources.

■Items provided

Cap / Jacket / Shirt / Pants / Rainwear

■Yuima Nakazato

Nakazato was born in 1985 and graduated from the Fashion Department of the Royal Academy of Fine Arts, Antwerp, in 2008.

In July 2016, he was chosen as one of the Paris Haute Couture Fashion Week’s official guest designers, and to this day he is the only Japanese designer to present his collections at Paris Haute Couture Fashion Week.

More recently, his retrospective exhibition “BEYOND COUTURE” was held at the Calais Lace and Fashion Museum, a public museum in France.

He designs costumes for stage performances, including for operas and ballets by the Boston Ballet in the U.S. and the Grand Théâtre de Genève in Switzerland. He is also the founder of the fashion award “FASHION FRONTIER PROGRAM” for the next generation of creators.

■Public viewing of attendant staff uniform for “Better Co-Being®”

Goldwin’s attendant staff uniforms for Osaka-Kansai Expo’s “Better Co-Being®” Signature Pavilion will be shown to the public for just two days on Friday, December 13, and Saturday, December 14, 2024, in our Tokyo headquarters’ event space on the first floor as a special exhibit of the “FASHION FRONTIER PROGRAM” exhibition. For more details, click the link below.

“FASHION FRONTIER PROGRAM” Exhibition press release (released on Wednesday, November 27, 2024): https://about.goldwin.co.jp/news/page-37030

*”Better Co-Being” is a registered trademark of the Japan Association for the 2025 World Exposition.

Contact Us Regarding This Information:

Goldwin Inc. Corporate Communications Office Tel.: 03-6777-9378