Effective June 2025, the Heads of the Research and Development Division and the Goldwin Business Division have been appointed as Directors. The two divisions serve as core functions in shaping the company’s future. The series’ second issue will feature one of them, Gen Arai from the Research and Development Division, who will talk about the Toyama Head Office—our mother factory serving as the core function for sports apparel development operations.

The Research and Development Division to Drive the Growth of Each Brand

“The Research and Development Division needs to serve as a bridge connecting our brands. It is my responsibility to make it happen,” said Arai upon starting the interview. The Toyama Head Office serves as the core function for our monozukuri (art of making things) operations. He oversees the development and production facilities there. After joining the company in 1991, he played a key role in elevating The North Face to a leading brand, under the leadership of Takao Watanabe, our current President and CEO. Subsequently, he reformed Goldwin, the company’s proprietary brand, and led product development as the Head of the Goldwin Business Division.

The company launched the Goldwin brand in 1958. Subsequently, we focused on developing skiwear for many years. In a way, our technological and design capabilities cultivated through skiwear development have helped achieve the current functionality of The North Face. However, as the ski boom peaked and then ended in the 1990s, the momentum of the Goldwin brand also waned. Instead, outdoor recreation emerged as a popular activity, driving the expansion of The North Face. For over a decade, Arai has dedicated his efforts to revitalizing our skiwear business, creating innovative products.

Crafting Products with Meticulous Attention to the Unseen Details

“For example, I have a favorite wind shell jacket. While most outerwear on the market focuses on windproofing, this particular shell uses a breathable fabric by design. What makes it great is that while it has windshell elements, it prioritizes a comfortable, breathable feel inside the garment by deliberately keeping it lightweight like a T-shirt or knit top and allowing some airflow… In other words, it’s a product concept that aims to create a new category of shell jackets, and I’m personally very passionate about it. In addition, its sewing specification features ultrasonic seam welding, a joining technology used to reduce bulk around the seam areas. Since this jacket does not have seam areas commonly found in most products, it is extremely comfortable to wear. So, to reiterate, even though it’s a shell jacket, you can wear it like a knit top or sweatshirt. I believe that this proposal or concept of new ways to wear a product is truly innovative… Well, I guess I got a bit carried away with the technical details there. (laughs).” (Arai)

Arai describes himself as “geeky” as his eyes light up and he can’t stop talking when it comes to textile design and sewing techniques. His approach also aligns with the foundation of Goldwin’s monozukuri.

“Using one phrase, our monozukuri practice can be described as “meticulously calculated but simple aesthetics.” This can also be considered functional aesthetics. When making things, we pursue excellence for invisible details. While the appearance of our products may be simple, they are created through layering multiple technologies and philosophies. This adds value to our products, translating into our strengths. I want to delve deeper into this area.” (Arai)

In fact, in his days as the Head of the Goldwin Business Division, he cultivated a new market through developing functional and simple products. One noteworthy initiative was the implementation of GORE-TEX® (*) for skiwear; GORE-TEX® is a highly functional material that is waterproof, breathable, and windproof.

“In those days, most of the skiwear on the market added value through lavish decoration. However, we wanted to create products that were simple, functional, and built with rugged integrity that could be used not only for skiing, but also for other various activities in backcountry and other outdoor settings. The skiing outer jacket featuring GORE-TEX® material and a simple design was priced over 100,000 yen. Although this was a challenging product to market, it was accepted by customers who understood the value of functional aesthetics. This is when I realized we could create a new a market.” (Arai)

Mother Factory Supporting the Core Brand Value

In the 1990s, as many Japanese apparel companies switched to offshore production, Goldwin maintained the Toyama Head Office as its domestic mother factory. “Only with the Toyama Head Office can we continue to create unseen value,” says Arai. The Toyama Head Office is our comprehensive monozukuri hub that consolidates various functions from material development and inspection to pattern design, sewing, sampling, and repair. Since assuming his current position as the Head of the Research and Development Division in April 2023, Arai has spent more than half of each month at the Toyama Head Office.

“There are very few places where we can communicate with customers across both timelines : the several years before products are released and the several years after they reach customers’ hands. At the Toyama Head Office, we develop and materialize innovative products through advanced fundamental research. In addition, we see products used by customers for several years received at the repair center on the premises.” (Arai)

The North Face has significantly grown thanks to numerous design requests coming to the Toyama Head Office, which has allowed the business to make progress through constantly working at maximum capacity to deliver on them. Arai thinks under these circumstances, his team has been a little too passive. Going forward, the Toyama Head Office is strongly expected to help the Goldwin brand grow as a partner developing even more innovative products.

“Rather than taking a passive approach to product development, we will proactively make proposals and enhance our technological capabilities, thereby bringing a healthy tension to product development across brand business units. I want the Toyama Head Office to initiate proposals as an organization capable of making more beautiful and functional products meeting the most demanding requirements.” (Arai)

Arai laughs as he describes craftspeople with advanced expertise and high aspirations as “geeks.”

“My colleagues in the fabric and fashion industries often describe me as a geek (laughs). I want my entire team at the Toyama Head Office to be geeks, too. It would be amazing to delve deeper into the outdoor and sports areas as both professional and personal passions. I hope that people with an obsession with materials and functionality, or geeks, will gradually grow here at the Toyama Head Office.” (Arai)

Passing down technology and know-how, which many Japanese manufacturers cite as a challenge, is also an important issue for the Toyama Head Office. The office will face a wave of generational transition within three to five years. Arai shows determination, saying they need to create a system for passing down techniques to the next generation, especially for the sewing function that heavily relies on seasoned craftsmanship.

“Each production phase requires highly specialized skills. In a way, the team at the Toyama Head Office is a group of artisans. Since becoming the Head of the Research and Development Division, I make sure to frequently check in on my team to nurture high aspirations in all the members.” (Arai)

Simultaneously, he is advancing efforts to revitalize the workplace by recruiting and hiring people with new perspectives and investing in capital to create new things.

“The purpose of the capital investment is not to boost productivity for mass production, but to enhance our R&D knowledge and create opportunities to leverage them. For the company to survive, we need to sell value. To that end, I will push forward with necessary reform.” (Arai)

Uncompromising and Consistent Commitment to New Material Development

Another important mission for Arai is to implement environmentally friendly monozukuri practices. Indeed, developing environmentally friendly materials is one of our priority challenges. For one related initiative, Goldwin Play Earth Fund, our corporate venture capital fund, invests in startups developing innovative sustainable materials.

“For the past year, we have simultaneously started multiple projects to develop new materials for the future. Although these initiatives are not easy with few clear answers available, we must act now for the sake of five to ten years from now. Of course, what we initiate now may turn out to be a wrong choice five years or ten years later. However, I believe it is crucial to keep moving forward while carefully exploring the right path and direction and correcting any errors.”

“Environmentally friendly monozukuri isn’t something we do ‘as much as possible,’—we do it completely. Simply using environmentally friendly materials does not make the product good. We need to pursue aesthetics and functionality at the same time. Innovative products may not be immediately understood. However, there certainly will come a day when customers will appreciate their value in the future. For our company to continue growing as a Japanese company with global competitiveness, we will continue discovering and proposing new value from the Toyama Head Office, which is our R&D hub.” (Arai)

*GORE-TEX® is a trademark of W.L. Gore & Associates.

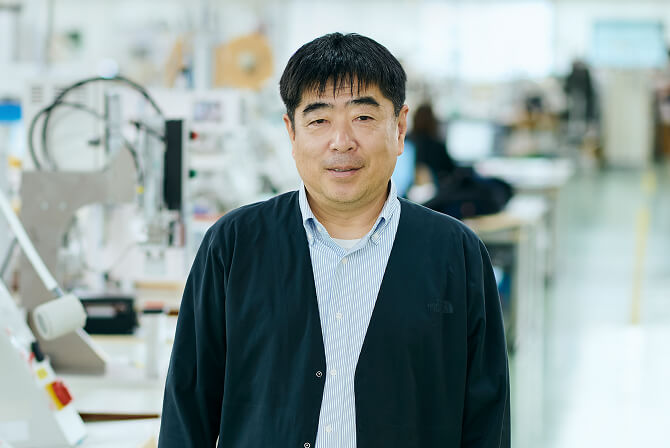

Gen Arai

Director CRDO*

Joined the company in April 1991. After serving as the head of the Compression Underwear Business Division, Goldwin Business Division, and Global HQ Goldwin Business Division, he was appointed as a Managing Director and the Head of the Research and Development Division. He is good at skiing and spends his days off actively, including mountain climbing and running. He is looking forward to photographing mountain and natural landscapes with a camera he recently purchased.

*Chief Research and Development Officer

The information provided, job titles and affiliations are current as of the time of the interview.

This serial Project is intended to help shareholders and investors understand our management policies, plans, financial situation, etc., and is not intended to solicit investment.